Coal-fired power plant

August 10, 2015 | Laura King-Homan | generation, how does that work

The eight generating stations in OPPD’s system are the work horses of the district, pumping electricity into the grid for our customers. Here’s a step-by-step look at how a coal-fired power plant works.

Arrival, unloading

- The coal arrives on a train car. One trainload of coal equals approximately 16,000 tons. For example, Nebraska City Station burns six to seven trainloads per week, while North Omaha Station burns two to three trainloads per week. In 2016, North Omaha Station’s Units 1-3 retired while Units 4 and 5 will be retrofitted with emission controls.

- After it is unloaded, the coal moves up a conveyor belt, as needed, to the crusher house, where it is reduced to marble-size pieces.

- The crushed coal then continues up the conveyor into the plant and stored in a bunker.

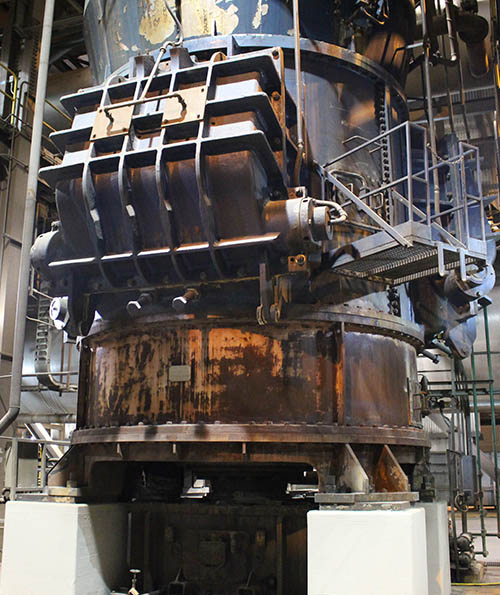

- From the bunker, the coal passes through a pulverizer, which grinds it until it is a fine powder. This makes the coal highly flammable, so it ignites and burns immediately when blown into the furnace.

- The heat generated when the coal burns in the furnace converts water in the boiler into steam.

Coal seen through a window as it is fed into one of the furnaces at Nebraska City Station. - Under tremendous pressure (2,415 PSI), the steam reaches a temperature of 1,000 degrees Fahrenheit. The pressurized steam is piped into the turbine, where it passes through a series of fan-like blades, which cause the generator’s rotor to turn. This produces electricity.

- From the generator, electricity flows to OPPD customers through a system of transformers and transmission lines.

- The exhaust, or spent steam, passes over a series of tubes through which cool water from the Missouri River flows. The steam condenses back to water and returns to the boiler. It heats up again before going through the cycle.

- A closed circuit confines the river water, which is used only for cooling. It is out of the river for less than 10 minutes before returning. Environmental studies show no significant adverse environmental effects on the river.

Laura King-Homan is the manager of Corporate Brand and Communication Operations, at Omaha Public Power District. She has nearly 20 years of print journalism and design experience, including the Omaha World-Herald.

View all posts by Laura King-Homan >