Video: Rubber goods go through the ringer

Tyler Christensen’s work could mean life or death to dozens of his fellow OPPD employees.

Christensen, maintenance worker second class, works in the Rubber Goods Testing area at OPPD’s Elkhorn Center in west Omaha. The rubber goods, which include sleeves, gloves and blankets, are one of the last lines of defense for employees who work around high-voltage equipment every day. Performing the tests in-house rather than by a third party is a point of pride for Christensen.

He also takes the responsibility personally. “I’ve got friends out there using them,” he said.

benefits of testing in-house

Shon Bourke, OPPD manager of Technical Training and Apprenticeship Programs, said testing the rubber goods in-house gives workers who use the goods confidence in their safety.

“There’s a relationship between the employee wearing the rubber goods and the employees testing them,” he said.

Jeff Richey, working line crew leader, summed up the importance of safe rubber goods with one sentence: “It’s the difference between going home at the end of the day or not.”

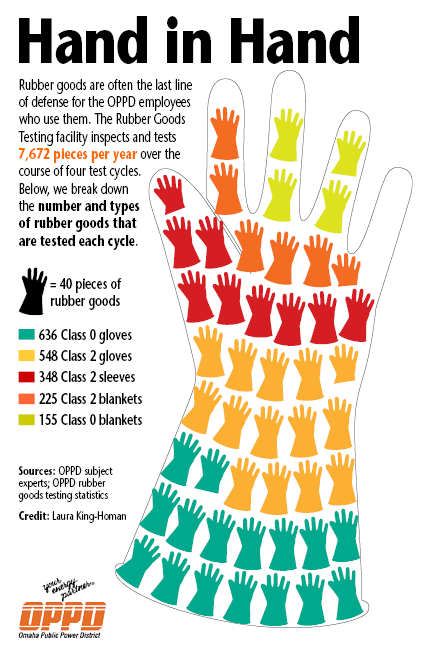

Among the rubber goods, there are two types of gloves and blankets and one type of sleeves. The two types, Class 0 and Class 2, are rated according to the amount of electric current they can withstand. Class 0 goods are rated to withstand up to 1 kilovolt of electricity while Class 2 goods can withstand up to 17 kilovolts.

The gloves and sleeves are part of a worker’s personal protection equipment. They are the last line of defense against serious injury when working around energized equipment. Rubber stops the circuit from completing. Blankets are among the equipment stocked on OPPD trucks to protect workers from energized equipment while they work.

safety in numbers

Each year, Christensen tests more than 7,500 pieces. The goods are divided into four, monthlong cycles throughout the year. Each piece is tested every other cycle. For example, one pair of rubber gloves is tested once in January and again in July.

An average of 70 pieces fail per cycle, Christensen said.

An employee preparing to work around energized equipment first puts on the rubber sleeves, which fasten around their shoulders, followed by the rubber gloves. Finally, workers add leather gloves.

Richey said wearing rubber gloves in frigid cold can be “like working with your hands in a bucket of ice.” The gloves lack of thermal insulation.

Besides line technicians, employees at OPPD substations, in underground vaults and at power plants also must wear rubber goods for protection.

test time

At the beginning of a testing month, large green bins of rubber goods line the hallway near the testing room. Each has a label from one of the 31 OPPD locations and departments from which they came.

Two pairs of gloves and sleeves are issued to each employee so they can alternate pairs. Testing occurs during four months of the year. Employees can request their rubber goods be tested at any time or ask for a replacement if they feel a piece is unsafe.

It costs around $1,000 to outfit an employee with rubber goods. That cost includes blankets assigned to the trucks, two pairs of gloves and a pair of sleeves.

A small price to pay for someone’s safety in the field.

Each glove and sleeve are cataloged in a database after testing is complete. After testing, Christensen matches the glove numbers and returns them to the employee.

important equipment

If employees take proper care of the rubber goods, including storing them in canvas bags, the goods will last a long time. In the field, employees use special bug sprays that don’t compromise the rubber, and powders that don’t contain metal, which can conduct electricity.

Richey, the working line crew leader, demonstrated a field test that starts by spinning the glove to capture air. The employee pinches the glove closed and listens for air escaping, spreading the fingers of the glove to look for wear and holes.

OPPD service centers also have equipment that allows employees to pump a glove full of air to double-check for leaks. Richey said one upgrade to the Class 2 gloves, a red interior and black exterior, makes tears and holes easier to see.

The relationship between an employee and his or her rubber goods is an important one, Richey explained.

“It’s our last line of defense and the first at the same time,” he said. “You always want to do everything right so that the rubber goods are there as the final protection.”

Laura King-Homan is the manager of Corporate Brand and Communication Operations, at Omaha Public Power District. She has nearly 20 years of print journalism and design experience, including the Omaha World-Herald.

View all posts by Laura King-Homan >